LBS 2023 AGM

Mannju

on

June 20, 2023

LBS Bina Group Berhad (“LBS” or the “Group”) is pleased to announce that it has successfully concluded its 23rd Annual General Meeting (“AGM”) today, which was conducted on a fully virtual basis.

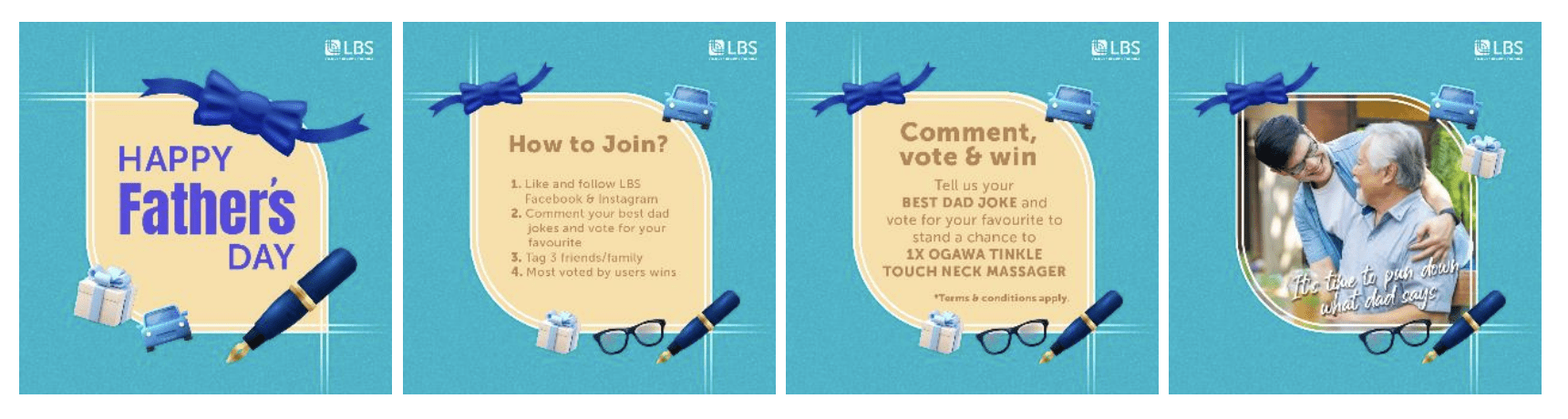

Father’s Day Giveaway 2023

Mannju

on

June 15, 2023

Father’s Day Giveaway (“My Best Dad Jokes”) (“Contest”)

The Contest is organised by LBS Bina Group Berhad (hereinafter known as “the Organiser”). By participating in the Contest, you agree to be bound by the following terms and conditions as stipulated herein (consisting of the General Terms and Conditions and the Specific Terms and Conditions) between you and the Organiser (“Contest Terms”). By participating in this Contest, you are deemed to have read and agree to the Contest Terms herein mentioned. You agree that the Organiser may include additional terms to and/or vary the Contest Terms at our sole discretion at any point of time and any additional and/or variation of the terms shall be incorporated by reference immediately at the point of time in which it is implemented. You are advised to visit this page from time to time to be updated of the latest Contest Terms.

In the event of any inconsistency between any terms and conditions stipulated in any of the Organiser’s marketing brochures, leaflets, buntings, or otherwise any other platforms and the Contest Terms stipulated herein, the latest Contest Terms shall prevail.

A. GENERAL TERMS & CONDITIONS

1. CAPACITY AND REPRESENTATION

1.1 To be eligible to participate in the Contest, you must be aged eighteen (18) and above in Malaysia or have attained an age of majority in the jurisdiction in which you are domiciled to enter legally binding contracts.

1.2 You acknowledge and agree that all information provided by you which will be relied upon by the Organiser is true, accurate, and not misleading. The Organiser reserves the right to request for more information from you in the event the information provided by you is deemed insufficient failure by which may result in your disqualification from the Contest.

1.3 You shall be responsible to update us immediately in the event that you discover that any information made by you is erroneous, outdated, or insufficient. Kindly note that failure by you to provide the necessary information to us may result in your disqualification from the Contest.

1.4 You further acknowledge that we will rely on any information provided by you and that any false, inaccurate, and/or misleading information may cause losses and damage to us. You agree to hold harmless and indemnify us, our directors, our employees, our agents, our affiliates, and any other third parties facilitating the Contest from the losses and damage suffered as a result of the false, inaccurate and/or misleading information provided by you.

1.5 You shall not use the Contest as a means or manner to facilitate or promote any illegal, immoral, violence, hate speech, racially disparaging, defamatory and/or fraudulent content (hereinafter be referred to as “Refrained Content”) wherein any evidence of such Refrained Content occurring out of this Contest, the Organiser shall not be made responsible whatsoever and you will be subjected to a disqualification by the Organiser.

1.6 By participating or entering this Contest, you are not violating any constitutive documents, applicable law, policies, regulation, rules, other terms, and conditions, and/or contracts that you have entered, agreed, or bound into with any third parties in any jurisdiction.

1.7 You will comply with all applicable laws, by-laws, rules, regulations, policies, instructions, directions, orders and/or directives from the Organiser, any governmental organization, and/or relevant authorities.

2. PRIVACY

2.1 All information provided by you shall be collected, stored, used, and retained by us in accordance with our Personal Data Protection Act Notice. You are to read, acknowledge and accept our Personal Data Protection Act Notice which is incorporated by reference herein and can be found at https://lbs.com.my

3. TAX AND DISBURSEMENTS FEES

3.1 You shall bear all expenses including but not limited to transportation, personal expenses, insurance, stamp duties, transfer fees, taxes, any other duties and/or any other costs, fees and/or related expenses incurred pertaining to the Prize (hereinafter defined).

3.2 You shall be solely responsible to declare your Prize winnings with the relevant tax authorities and pay for any levy, duty, charges, and tax that is imposed (if any). The Organiser shall not in any way be held liable to pay any charges, tax, levy, fines and/or duty that are imposed on the Winners by the relevant tax authorities for the Prize winnings.

4. PRIZES

4.1 The Organiser shall not assume any liability and responsibility whatsoever in the event of any mishaps, injuries, damages, death, claims and/or accidents suffered by your participation in the Contest and/or from the use of the Prizes.

4.2 You shall hold the Organiser harmless against any liability and claims and agree to indemnify the Organiser completely for any claims, damages, losses, and liability arising from and/or in relation to your use of the Prizes.

4.3 You agree and acknowledge that the Organiser provides no representation or warranty of any kind whatsoever in respect of any defect or other faults in relation to the Prize, and that the Prize displayed in any marketing or promotional materials are for illustration purposes only which may not depict the actual color, material, model, and/or specification of the actual Prize.

4.4 The Organiser shall not be liable to compensate and/or rectify any defect or other faults in the Prizes. You shall contact and refer to the supplier, manufacturer, distributor and/or reseller of the Prizes in the event that you have any queries, concerns, and issues regarding the Prizes.

4.5 The Organiser shall not be liable to compensate and/or rectify any defect or other faults in the Prizes. You shall contact and refer to the supplier, manufacturer, distributor and/or reseller of the Prizes in the event that you have any queries, concerns, and issues regarding the Prizes.

4.6 You agree that the Prize is non-transferable, non-refundable, non-exchangeable for cash without the Organizer’s express written consent. The Organizer reserves the right to substitute any Prize with that of a similar value without prior notice to you.

5. INDEMNITY

5.1 You agree to indemnify and keep indemnified the Organiser, its directors, employees, agents, affiliates, and any other third parties facilitating the Contest against all liabilities, losses, damages, and expenses which the Organiser may incur or suffer as a result of or in connection with and any breach and violation of Contest Terms herein or any representation or warranty given by you.

6. PROMOTIONAL MATERIALS

6.1 You agree that the Organiser shall have the right to interview you, take photographs, and videos as well as use your personal details which shall include your name(s) for our marketing campaign materials for the purposes of advertising, trade and/or publicity in accordance to the Privacy clause above. You acknowledge that any interview results, photographs and videos shall be solely owned by us.

7. MISCELLANEOUS

7.1 The Organiser reserves the right at its sole discretion to suspend, modify, extend, delay, or terminate the Contest at any time without prior notice to you.

7.2 Any decisions taken by the Organiser are final and binding on you and the Organiser shall not be obliged to entertain any queries, claims, requests, or correspondences after the decision of the Organizer has been made.

7.3 The Organiser shall have the absolute right to disqualify any individual that it determines to be tampering with and/or disrupting the operations of the Contest, and/or to be acting in breach or potential breach of these Contest Terms.

7.4 Any provisions applicable to this Contest which is prohibited or unenforceable under any law or regulation shall be ineffective to the extent of such illegality, voidness, prohibition, or unenforceability without invalidating the remaining provisions.

8. DISCLOSURE

8.1 This Contest is in no way sponsored, endorsed or administered by, or associated with Meta Platforms, Inc (formerly known as Facebook, Inc). The Organiser expressly excludes any losses, claims, and/or actions arising from any glitch, malfunction, shut down, and/or otherwise use arising specifically from Facebook, Instagram or any platform (whether or not derivative) from Meta Platforms Inc.

B. SPECIFIC TERMS AND CONDITIONS

The Contest Period

The period shall commence from 18 June 2023 and shall end on 22 June 2023, 12:00 am (“Contest Period”). The Organiser reserves the absolute right to extend or vary the Contest Period at its sole discretion. All entries received before and after the Contest Period shall be invalid and will not be entertained by the Organiser.

Method of Participation

In this contest, the participants will have to share their best” dad joke” in the comment section of the Contest posting (“Contest Posting”) to stand a chance to win prizes. They would then need to make sure their ‘dad joke’ in the comment would get the most likes.

To participate in the Contest and be eligible to win the Prizes, participants must: –

i. “LIKE” and “FOLLOW” the Organiser’s Facebook (@LBSBinaGroup) and Instagram (@lbsbinagroup) social media platforms respectively and remain liked and followed throughout the Contest Period;

ii. Participants to comment on the Contest Posting their best “dad joke” during the Contest Period.

iii. Tag three (3) unique and legitimate accounts that you are connected to on Facebook/Instagram in the same Content Posting.

*Only One (1) entry is allowed for each participant.

Contest Visual / Posting

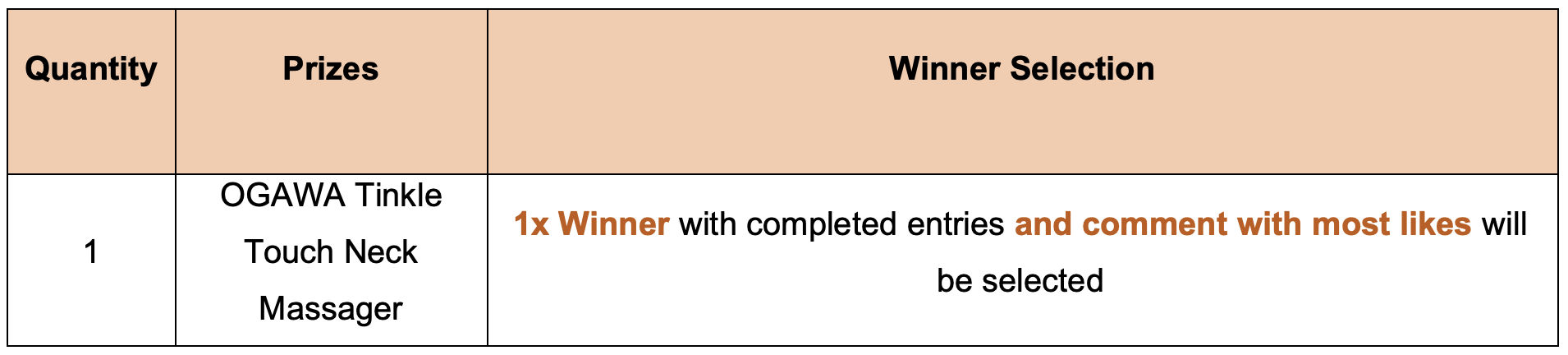

Contest Prizes

The Organizer shall announce the winner of the Contest latest by Friday, 30 June 2023 (“Winner Announcement Date”).

Selection of Winners

Winner will be selected within five working days of this Contest’s closing date. The winner will be selected by the most voted on the post comments from those valid entries received during the Contest Period.

Prize Redemption Details

- The winner shall within seven (7) days upon being selected, be required to send their personal details including but not limited to their full name, email address and contact number through Facebook or Instagram ‘Direct Message’ (DM) function for the Organizer to correspond with the winner accordingly for prize claiming process.

- They are required to collect their respective OGAWA Tinkle Touch Neck Massager at LBS Bina Group, Plaza Seri Setia, Petaling Jaya on a date and time to be informed by the Organiser.

- The Organiser will not be held responsible and reserves the right to forfeit and/or assign the prizes to another participant should the initial winner(s) fail and/or neglects to provide the required details within stipulated time frame and/or to comply with the instructions of the Organizer.

- The Organiser will not be held responsible and reserves the right to forfeit and/or assign the prizes to another participant should the initial winner(s) fail and/or neglects to collect the prizes within 90 days from date of Winner Announcement Date.

DISQUALIFICATION

The Organizer reserves the right to disqualify: –

a) Any submissions in the above-mentioned terms and conditions in the event that; the submission of any photo(s), screenshot(s) and/or image(s) relevant are manipulated, blur, unclear, and/or containing inappropriate content, including but not limited to vulgarity, obscenity, lewd, pornographic or violent material, or materials which promote violence or which disparages the Organizer or any other person or entity, or contain trademarked or copyrighted material.

b) Any entry which the Organiser considers to have been made in breach of this Contest terms and conditions.

Term of Reference of Risk Management Committee

Mannju

on

June 7, 2023

1. OBJECTIVE

The principal objective of the Risk Management Committee is to assist the Board of Directors in their responsibilities to identify, assess and monitor key business risks to safeguard shareholders’ investments and the company’s assets.

2. COMPOSITION

(a) The Risk Management Committee (“RMC”) shall be appointed by the Board and shall comprise no fewer than 3 in number.

(b) The members of the RMC shall elect a Chairman from among their number.

(c) In the event of any vacancy in the RMC resulting in the number of members being reduced to below 3, the Board shall, within one (1) month fill the vacancy.

(d) The Board shall have the discretion as it deems fit to rescind and/or revoke the appointment of any person(s) in the RMC.

3. MEETING

(1) The quorum for the meeting shall be 3 members

(2) The RMC shall meet at least twice a year. However, additional meetings may be called at any time at the RMC Chairman’s discretion.

(3) Meetings of the Committee shall be summoned by the Secretary of the Committee at the request of any member thereof. Notice of each meeting confirming the venue, time and date together with an agenda of items to be discussed, shall be forwarded to each member of the Committee not less than three (3) working days prior to the date of the meeting.

(4) A resolution in writing signed by a majority of the Committee Members for the time being shall be as valid and effectual as if it had been passed at a Meeting of the Committee duly called and constituted. Any such resolution may consist of several documents in like form each signed by one (1) or more Committee Members. Any such document, may be accepted as sufficiently signed by a Committee Member if transmitted to Company by telex, telegram, cable, facsimile or other electrical or digital written message purporting to include a signature of a Committee Member.

(5) The Company Secretary shall be the Secretary of the Committee.

(6) For good governance, each member must attend at least 50% of the meetings held within the year, failing which Nomination and Remuneration Committee will decide on the member’s disqualification.

4. REPORTING

The Secretary shall circulate the minutes of meetings of the Committee to all members of the Committee. Minutes of each meeting shall be duly entered in the book provided therefor. The Chairman shall report the proceedings of each meeting to the Board.

5. ROLES AND FUNCTIONS

The RMC has the overall responsibility for overseeing the risk management activities of the Group, approving appropriate risk management procedures and measurement methodologies across the organization as well as identification and management of strategic business risks of the Group. Its primary roles include the following:-

a) To promote the Enterprise Risk Management (ie. risk awareness and training) and to ensure that the risk management process and culture are embedded throughout the Group.

b) To formulate the Risk Management Policy of the Group and to ensure the implementation of the objectives outlined in the Risk Management Policy and compliance with them.

c) To provide routine quarterly reporting and update the Board of Directors on key risk management issues as well as ad-hoc reporting and evaluation on investment proposals.

d) To review the Statement on Internal Control for inclusion in the Company’s Annual Report and to recommend the same for the approvals of the Audit Committee and the Board.

e) To ensure that management and other relevant parties provide the Committee with adequate information to understand the significant risks to which the Company is exposed.

f) To review the Company’s procedures, policies and techniques to measure the Company’s risk exposures and to identify, evaluate and manage the significant risks to which the Company is exposed, including in the areas of market, operational, liquidity, credit, regulatory and reputation risk.

g) To review and to approve risk principles, policies and procedures recommended by management and the related management programs to ensure compliance with the related regulatory requirements.

The RMC delegates to the respective Heads of Department the responsibility for identification and management of operational risks, software management, training and ensuring effective implementation and maintenance of Risk Management Policy and that all personnel adhere to its mandate.

The Heads of Department shall assist the RMC by assuming direct responsibility for the routine risk management activities within the organization. They shall provid

5.1 Routine Roles & Responsibilities

(a) Provide quarterly reporting and update on operations of the Enterprise Risk Management framework to the Board.

(b) Review Enterprise Risk Profile for effectiveness of management of risks.

(c) Evaluate any new risks identified by the Heads of Department.

(d) Follow-up on management action plans reported by the Heads of Department.

(e) Responsible for ensuring that strategic business risks are considered.

5.2 Risk Evaluation of Investment Proposals

(a) Propose to the Board, the monetary threshold and nature of proposed investments that require the RMC’s evaluation and endorsement before submission to the Board.

(b) Review investment proposals which meet the requisite threshold.

(c) Review and feedback on evaluation of investment proposals to the Board for final decision.

6. REVIEW OF TERM OF REFERENCE

This Term of Reference has been approved by the Board and is made available for reference on the Company’s corporate website and internal computer networking system.

It shall be reviewed by the Committee and update whenever necessary to ensure its effective implementation. Any subsequent amendments to the Policy should be approved by the Board upon recommendation of the Committee.

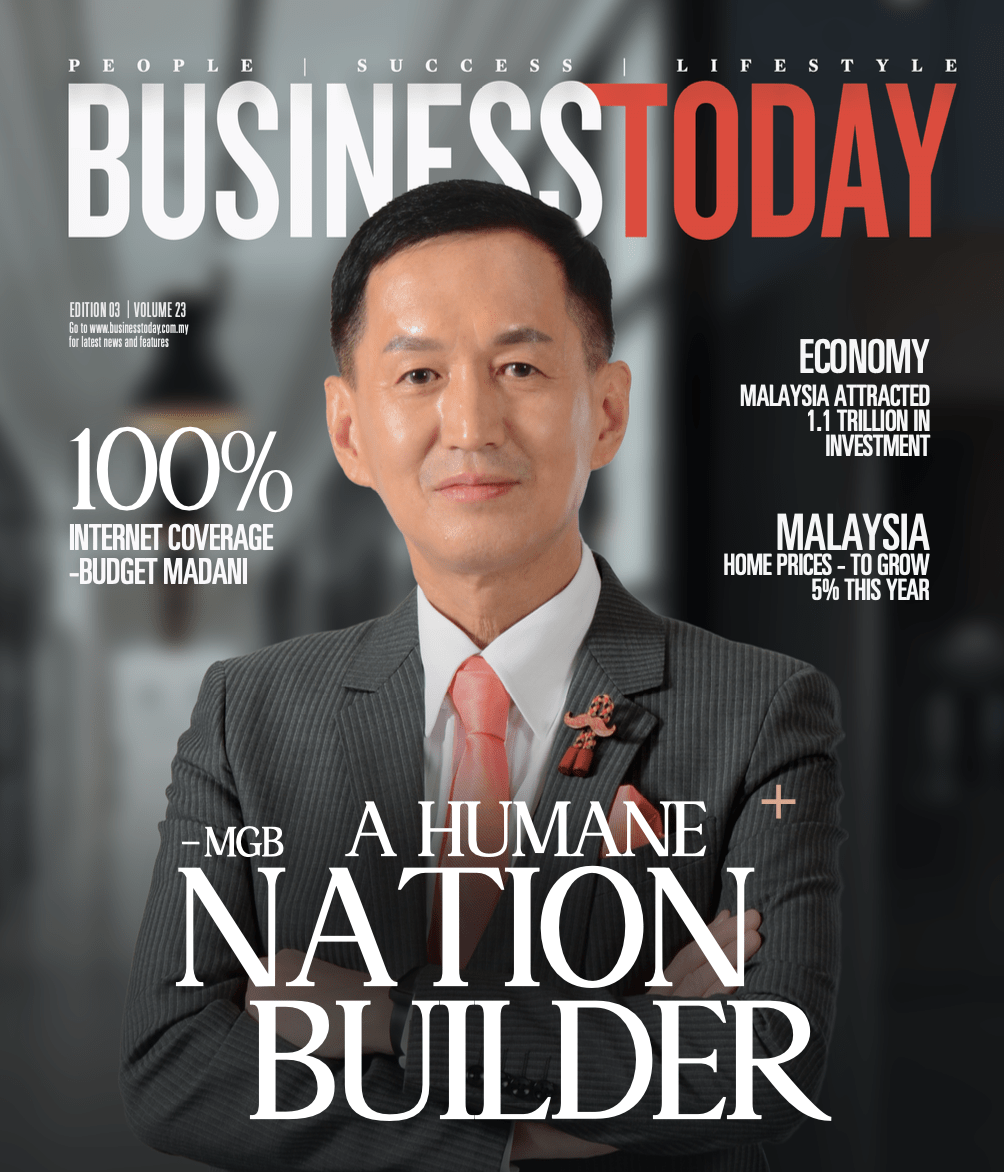

Tan Sri Lim Hock San honoured Ir title by Board of Engineers Malaysia

Mannju

on

June 6, 2023

The Executive Chairman of LBS Bina Group Berhad, Tan Sri Ir Lim Hock San, has been awarded the honourable title ‘Ir,’ joining the esteemed ranks of Malaysian professional engineers. Congratulations Tan Sri!

LBS Bina Brings Forth Meeting with Agong and Chief Minister of Melaka for Fujian Delegation

Mannju

on

June 6, 2023

LBS Bina Group Berhad continues to actively promote the attractiveness and viability of investing in Malaysia to China and has subsequently two sharing sessions for prominent leaders from the Fujian Government in China which were on a reciprocal visit to Malaysia following the Prime Minister, YAB Dato’ Seri Anwar bin Ibrahim’s official visit to China in April 2023.

One of the sharing sessions was a high-tea at Mandarin Oriental, Kuala Lumpur, graced by KDYMM His Majesty Seri Paduka Baginda the Yang Di-Pertuan Agong Al-Sultan Abdullah Ri’ayatuddin Al-Mustafa Billah Shah Ibni Almarhum Sultan Haji Ahmad Shah Al-Musta’in Billah. As for the other meeting is with the delegation of the Fujian Government with the presence of the Chief Minister of Malacca, YAB Datuk Seri Ab Rauf bin Yusoh, held at St. Regis Kuala Lumpur, in which he highlighted the prospective collaborations to be explored, focusing on the huge potential within the Melaka Waterfront Economic Zone (M-WEZ).

———————————————————————————————–

Facebook: https://bit.ly/LBSBina_Facebook

Instagram: https://bit.ly/InstagramLBSBina

Twitter: https://bit.ly/twitterLBSBina

Linkedin: https://bit.ly/LinkedInLBSBina

Visit our website here: https://bit.ly/WebsiteLBSBina

LBS Brings Forth Meeting with Agong and Chief Minister of Melaka for Fujian Delegation

Mannju

on

June 6, 2023

LBS Bina’s recent business-sharing sessions with the Fujian government delegation graced by The Yang Di-Pertuan Agong have garnered television interview opportunities from media publications namely BERNAMA, Astro AEC, Astro AWANI, TV3, and 8TV, where the Executive Chairman of LBS Bina and Leaptec Engineering, Tan Sri Ir. Lim Hock San emphasizes the prospective collaborations to be explored, focusing on the vast potential within the Melaka Waterfront Economic Zone (M-WEZ). Television coverages of the television interviews can be found here:

This month, Tan Sri Ir. Lim Hock San joins other renowned figures in the property industry to enlighten the market on the key differences between leasehold and freehold, and how homeownership is above and beyond just the title. Read more about this interview here.